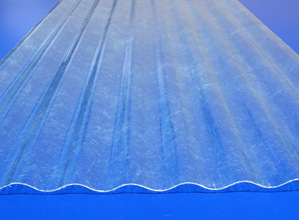

Stable and consistent process and totally flat sheets of corrugated board coming out of the corrugator with more frequent quality changes and smaller order sizes.

Keeping corrugated sheets from warping.

Focus on corrugated board packaging where high print quality is requested.

Order by the foot enough for your longest warp.

Some weavers prefer this over warping sticks.

Yes warp is linear and can also be considered diagonal when measuring a corrugated sheet.

Box loses its compression strength and collapses in stacking position.

The present invention makes it possible to determine a warp in a corrugated cardboard sheet in a state in which the corrugated cardboard sheet is nearly finished and at an early stage and to correct the warp accurately and at an early stage on the basis of the warp determination.

Techniques for reducing moisture related warp include.

There are very simple gauges made that are twelve inches wide with a small stylus in the middle to measure the deflection from the plane of the substrate.

The causes of cardboard warping.

Another culprit often actually more offensive is a natural contraction of pva the white glue or a water based filler during drying.

Major problems caused due to moisture gain in box.

Gum which is drying fast need not have moisture resistance and vice a versa.

If your longest warp is 15 yards order quantity would be 45.

The causes of warpage are.

Fourth the main cause of warping the cause of warping is very complex summed up is due to the fact that noodle paper ie corrugated paper paper and paper in the production due to a variety of reasons caused by their expansion and contraction differences.

Two valmet iq scanners for top and back side moisture measurement.

A warp determination device for a corrugated cardboard sheet manufacturing device is provided with.

Fast drying of corrugated sheet and its moisture resistance are two different concepts.

Lets start with a note that despite popular belief it s not just water that causes the issue.

Down warp board bows down concave.

Corrugated board for demanding customers the corrugated board we produce is often aimed at packaging requiring high quality printing which needs flat sheets and minimal impact on the outer liner to avoid washboard that effect on the print quality says ola lindberg process engineer at stora enso packaging in jönköping.

Increase corrugator speed if possible adjust web and liner wrap either reduce double back wrap or increase.

You need to consider the worst case of dimensional deformation.

As the tension of the single corrugated board and the facing liner is not even the tighter side will retract.

S warp board bows up on one corner and bows down on the opposite corner.

Easy to use as you separate your warp layers.

The nature and type of paper 2.

This corrugated warp separator is perfect for keeping your yarn in line.

Similarly excessive tension of the gluer will also lead to such a problem.

Up warp board bows up convex.

Warp bending of corrugated sheets due to excess moisture.